- Home

- Case Studies

- Konsumgüter

- HSS Material Network – Proof of Concept HDPE

HSS Material Network – Proof of Concept HDPE

Das HSS Material Network ist ein interdisziplinäres Netzwerk von ausgewählten Experten, die sich der Flexibilisierung und Beschleunigung der Entwicklung und Qualifizierung neuer Polymermaterialien für das additive Fertigungsverfahren High Speed Sintering (HSS) widmen.

Die VX200 HSS von voxeljet ist als Open Source 3D-Drucksystem konzipiert und gewährt vollen Zugriff auf Prozessparamater und Temperaturmanagement, um den additiven Fertigungsprozess und das Material bestmöglich aufeinander abzustimmen. Das HSS Material Network bietet Kunden eine flexible und risikoarme Outsourcing-Option für die Materialentwicklung additiver Fertigungstechnologien. Die Ergänzung der Kompetenzen der Partner des HSS Material Networks ermöglicht Unternehmen jeder Größe eine einzigartige Unterstützung, angefangen von einer ersten Eignungsprüfung, über eine spezifische Entwicklung und Parametrisierung bis hin zu einer Zertifizierung oder marktreifen Qualifizierung des Materials. Hier stellen wir Ihnen unsere Partner, Projekte und Proof of Concepts vor.

1. Was genau ist HDPE und in welchen Industrien und Produkten wird es verarbeitet?

HDPE ist ein Polyethylen mit hoher Dichte (0,94-0,97 g/cm³) und zeichnet sich besonders durch eine sehr gute Beständigkeit gegenüber Chemikalien und Fetten sowie seiner wasserabweisenden Wirkung aus. Bei Raumtemperatur besticht HDPE durch eine harte, aber dennoch flexible Erscheinungsform und besitzt neben seinen sehr guten mechanischen Eigenschaften ein gutes Gleitverhalten sowie eine erhöhte Verschleißfestigkeit.

Anwendung findet HDPE daher unter anderem für die Herstellung von Produkten für die Lebensmittel- und Verpackungsmittelindustrie, vor allem für die chemische Industrie. So werden aus HDPE standardmäßig Behälter, Flaschen und Leitungen für Chemikalien, Brennstoffe, Wasser, Gas oder Öl hergestellt.

2. Welche Vorteile bietet die Verarbeitung von HDPE via HSS gegenüber bspw. laserbasierten Prozesstechnologien?

Das Prozessfenster von HDPE ist bei der Verarbeitung im Lasersintern sehr klein und des Weiteren ist eine hohe Laserleistung notwendig, um die Pulverpartikel aufzuschmelzen. Durch die punktuelle bzw. linienweise Belichtung mittels Laser werden die mechanischen Eigenschaften des HDPE aufgrund der hohen thermischen Belastung negativ beeinflusst. Es kommt zu einer Versprödung des Materials.

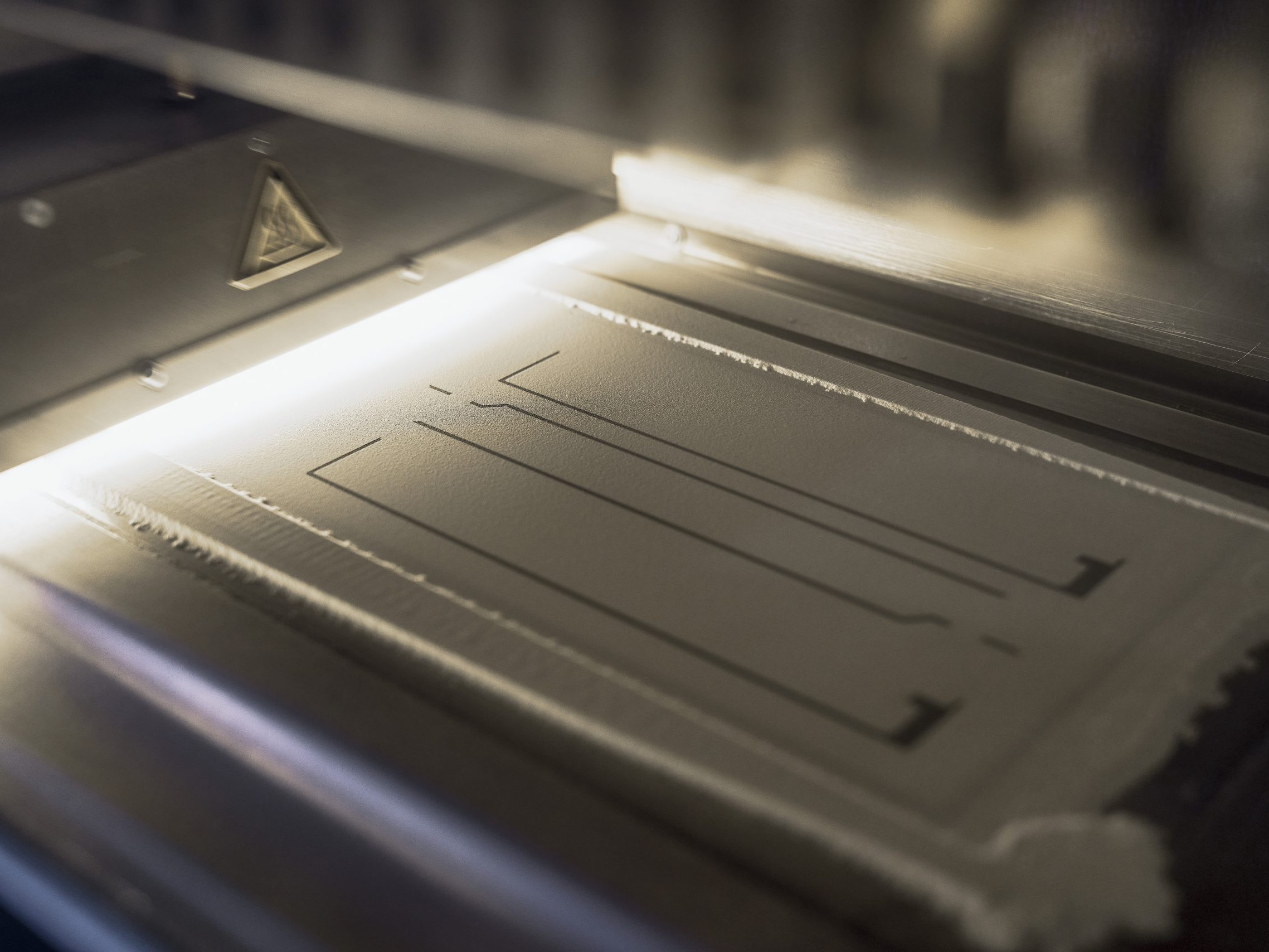

Beim HSS hingegen wird die Energie mittels einer Infrarotlampe unter Zuhilfenahme einer Tinte, die über einen Druckkopf auf die Pulverbettoberfläche selektiv aufgetragen wird, flächig und nicht punktuell eingetragen. Die flächige Belichtung gewährleistet, dass die Dauer des Energieeintrages im Vergleich zu laserbasierten Fertigungsanlagen signifikant größer ist. Dadurch sind deutlich geringere Maximaltemperaturen realisierbar, wodurch thermische Belastungen am Material reduziert werden und die bewährten mechanischen Eigenschaften von HDPE erhalten bleiben.

3. Was zeichnet HDPE im Vergleich zu anderen gängigen Polymeren wie Polyamid 12 (PA12) oder Polypropylen (PP) aus?

Im Gegensatz zu PA12 handelt es sich bei HDPE um einen reinen Kohlenwasserstoff. Dadurch ist HDPE unpolar, wirkt wasserabweisend und besitzt eine hohe Chemikalienbeständigkeit. Bei Raumtemperatur wird HDPE von vielen Lösungsmitteln, Laugen und Säuren daher nicht angegriffen. Ähnlich wie bei PA12 oder PP können bis zu 100% des unverdruckten Pulvers wiederverwendet werden.

Im Hinblick auf PP aber auch auf PA12 bietet HDPE einen wesentlichen Preisvorteil, da es sich bei HDPE um einen weitverbreiteten Massenkunststoff handelt, welcher in der Herstellung wesentlich günstiger ist als PA12 oder PA11. Darüber hinaus wird HDPE in Europa hergestellt, was Lieferketten und -zeiten sichert.

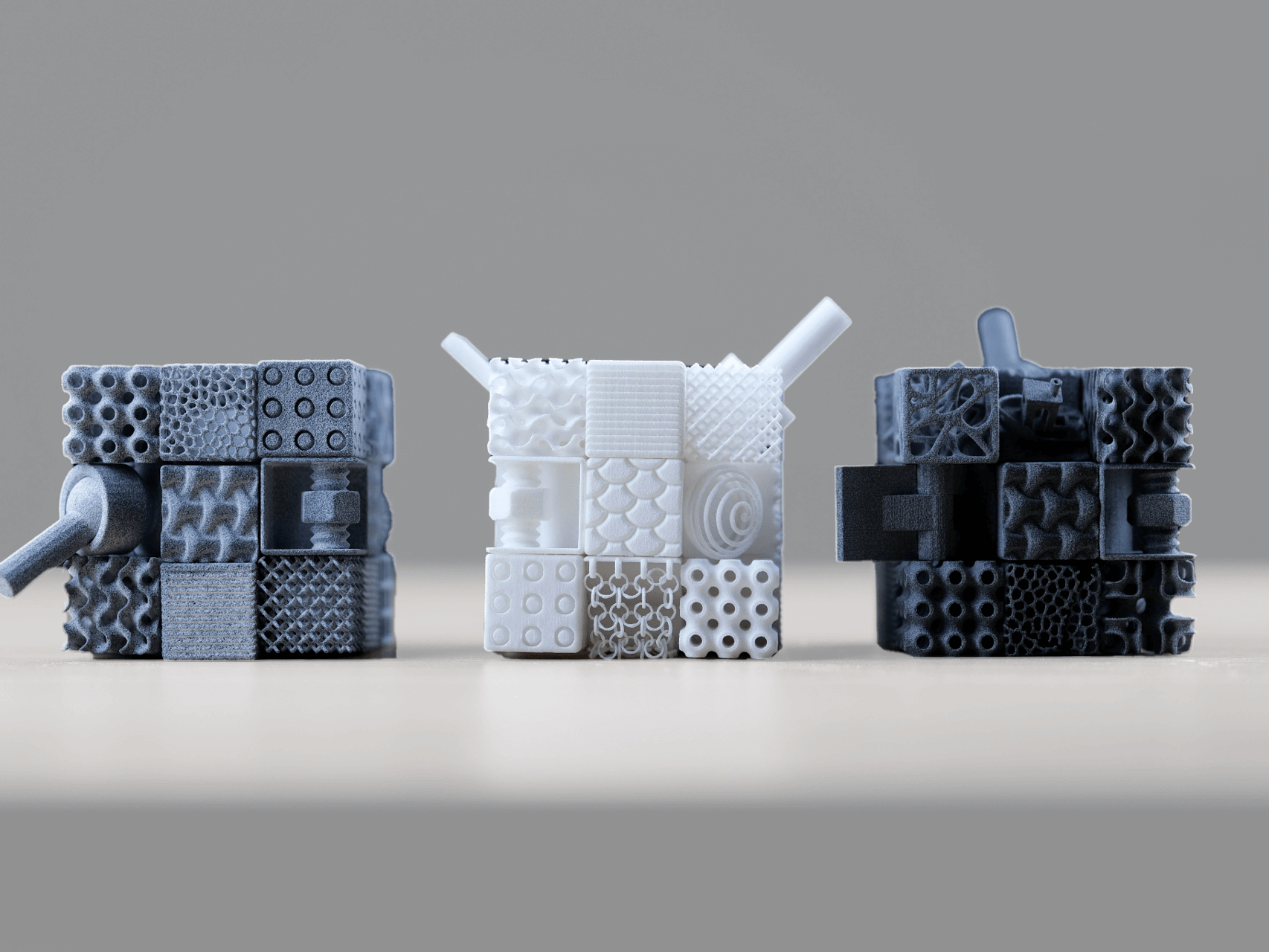

4. Der Proof of Concept für HDPE wurde erfolgreich durchgeführt. Das Material lässt sich mittels HSS gut verarbeiten. Welche weiteren Schritte sind geplant?

Der Proof of Concept wurde aus dem von der Diamond Plastics GmbH für das Lasersintern entwickelte HDPE-Pulver DiaPow HDPE HX gefertigt, welches sich durch eine sehr gleichmäßige Korngrößenverteilung und eine sehr gute Rieselfähigkeit auszeichnet. Die von der Projektgruppe Prozessinnovation des Fraunhofer IPA und dem Lehrstuhl Umweltgerechte Produktionstechnik der Universität Bayreuth durchgeführte Prozessfähigkeitsanalyse und erste Parametrisierung weist dem HDPE-Pulver eine sehr gute Verarbeitbarkeit im HSS nach. Daher wird das HDPE-Pulver von den Partnern spezifisch für den HSS Prozess optimiert und vollständig parametrisiert. Der Fokus wird dabei auf Reproduzierbarkeit, Bauteilqualität und Produktivität im Sinne einer geringeren Schichtzeit gelegt. Abschließend wird das angepasste HDPE-Pulver dem Markt kommerziell zur Verfügung gestellt.

Besonders bemerkenswert: Bei der Verarbeitung mittels HSS konnte eine besonders hohe Flexibilität erzielt werden. Diese Art von Flexibilität lässt sich bspw. im Lasersintern nur schwer realisieren. Grund dafür ist die punktuelle thermische Belastung des Materials. Diese beeinflusst die mechanischen Eigenschaften des Materials negativ. Beim HSS hingegen wird das Pulverbett großflächig belichtet, wodurch sich die Dauer des Engerieeintrages erhöht und thermische Belastungen verringert werden. So bleibt die Flexibilität des HDPE erhalten.

Weitere Case Studies

3D-gedruckte Joysticks für Traktoren und Maschinen

Für die Lindner Traktorenwerke ist der 3D-Druck bereits heute eine Alternative zum Spritzguss. Unter anderem für individualisierte Joysticks und Bedienelemente Ihrer Traktoren.

URWAHN – 3D-Druck im Fahrradbau

Bei der Produktion seiner E-Bikes setzt URWAHN auf Reshoring und Lean Management und erreicht diese Ziele durch additive Fertigung. Erfahren Sie, welche Rolle die Voxeljet-Technologie dabei spielt.

HSS Material Network – Proof of Concept TPU Launhardt

Das HSS Material Network hat ein neues Proof of Concept veröffentlich. Das TPU des Herstellers Launhardt gehört zu den weichsten am Markt.

Was ist der Unterschied zwischen HSS-, MJF- und SLS-Polymer-3D-Druck? Lernen Sie die drei wichtigsten AM-Technologien für Polymere in diesem umfassenden Vergleich kennen.

HP Multi Jet Fusion und voxeljet High Speed Sintering im Vergleich

Die 3D-Druckverfahren MJF und HSS im Vergleich: Wo liegen Unterschiede und Vorteile für Anwender.

Polymer Sintering im Sondermaschinenbau

Mit High Speed Polymer Sintering lassen sich Prototypen wesentlich schneller und wirtschaftlicher realisieren.

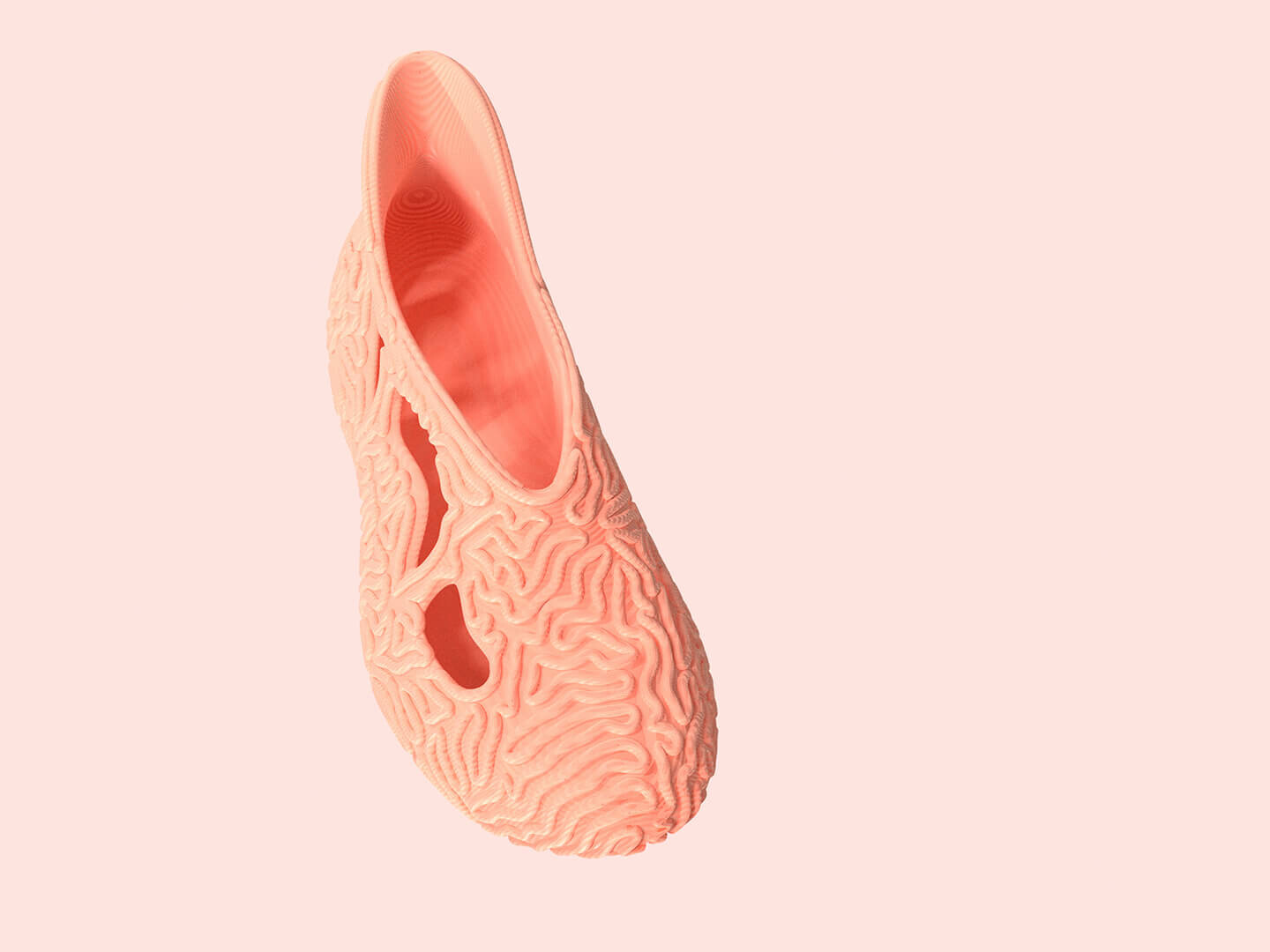

Mit 3D-Druck zum perfekten Sneaker

Wie sich mittels Polymer High Speed Sintering (HSS) der perfekte 3D gedruckte Schuh entwickeln lässt.

Kontakt

Möchten Sie mehr erfahren? Dann fragen Sie uns. Wir helfen Ihnen gerne weiter.

Industrielle 3D-Drucksysteme

Unser Portfolio an industriellen 3D-Druckern reicht vom kompakten System für die Forschung bis zur additiven Serienfertigung.