Industrieller 3D Drucker

Der VX200 3D-Drucker

Flexibler Einstieg in den multimaterialen industriellen 3D-Druck

300mm

lange Produkte

254dpi

hohe Auflösung

9l

Bauvolumen

3D-Druckfür Forschungund Entwicklung

Freie Parameter und eine einfache Bedienung: Der VX200 3D-Drucker bietet das höchste Maß an Flexibilität in puncto Materialentwicklung und Prototypenbau in der voxeljet System-Serie. Ob neue Binder- und Pulverkombinationen oder die schnelle Produktion von Bauteilen zur Eigenschaftsüberprüfung. Mit der voxeljet Open-Source-Software können Prozessparameter auf individuelle 3D-Druck-Materialien abgestimmt werden. Durch den hochproduktiven Binder-Jetting-3D-Druck-Prozess sparen Sie für die Materialoptimierung und können erste Designiterationen schneller und kostengünstiger umsetzen.

Als das kompakteste Modell aus der voxeljet Serie ist der VX200 3D-Drucker prädestiniert für den Einsatz in der Forschung und Entwicklung. Denn mit seinen Stellmaßen findet er auch in kleineren Räumen bequem Platz und bietet dabei höchste Effizienz und Flexibilität. Testen Sie neue Multimaterialsets schnell und einfach.

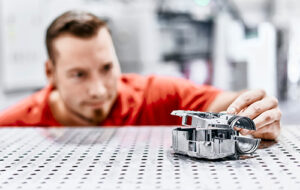

Neben der Forschung und Entwicklung spielt die VX200 ihre Stärken auch in puncto Prototypen- und Ersatzteilfertigung aus. Die hochauflösenden, piezoelektrischen Druckkopfmodule bieten höchste Leistungsstabilität und ermöglichen – je nach Material – eine Auflösung von bis zu 600 dpi. So ist der VX200 3D-Drucker in der Lage, selbst komplexeste Bauteilgeometrien schnell und mit beeindruckender Präzision zu realisieren. Verkürzte Liefer- und Entwicklungszeiten sind das Resultat.

Im Hinblick auf Materialverarbeitung bietet die VX200 eine enorme Vielfalt. Sie kann wahlweise verschiedene Sande, Keramiken oder auch Polyamide verarbeiten. Das eröffnet ein breites Spektrum an Einsatz- und Anwendungsmöglichkeiten und macht die VX200 zu einem multimateriellen 3D-Drucksystem.

Smart bedient

Die VX200 kann viel – aber die Bedienung bleibt dank eines durchdachten ergonomischen Konzepts ganz einfach.

Kompakt

Ohne notwendige Peripheriegeräte findet die VX200 auch in kleineren Produktionsbereichen oder Forschungslaboren Platz.

Materialvielfalt

Ob Sand, Kunststoff oder Keramik. Die VX200 ist multimateriell und kann alle gängigen voxeljet Materialsysteme wirkungsvoll und leistungsstark verarbeiten.

Innovation leicht gemacht

Erforschen Sie neue Materialien und Möglichkeiten für den 3D-Druck dank Open-Source-Software und frei einstellbarer Prozessparameter.

Kosteneffizient

Werkzeuge oder Formmodelle sind für den 3D-Druck nicht notwendig. Davon profitiert insbesondere die Wirtschaftlichkeit der Supply Chain.

Präzise im Detail

Mit einer Auflösung von bis zu 254 dpi, je nach Materialkonfiguration, druckt die VX200 selbst die feinsten Bauteile mit beeindruckender Präzision.

Einsatzgebiete des VX200 3D-Druckers

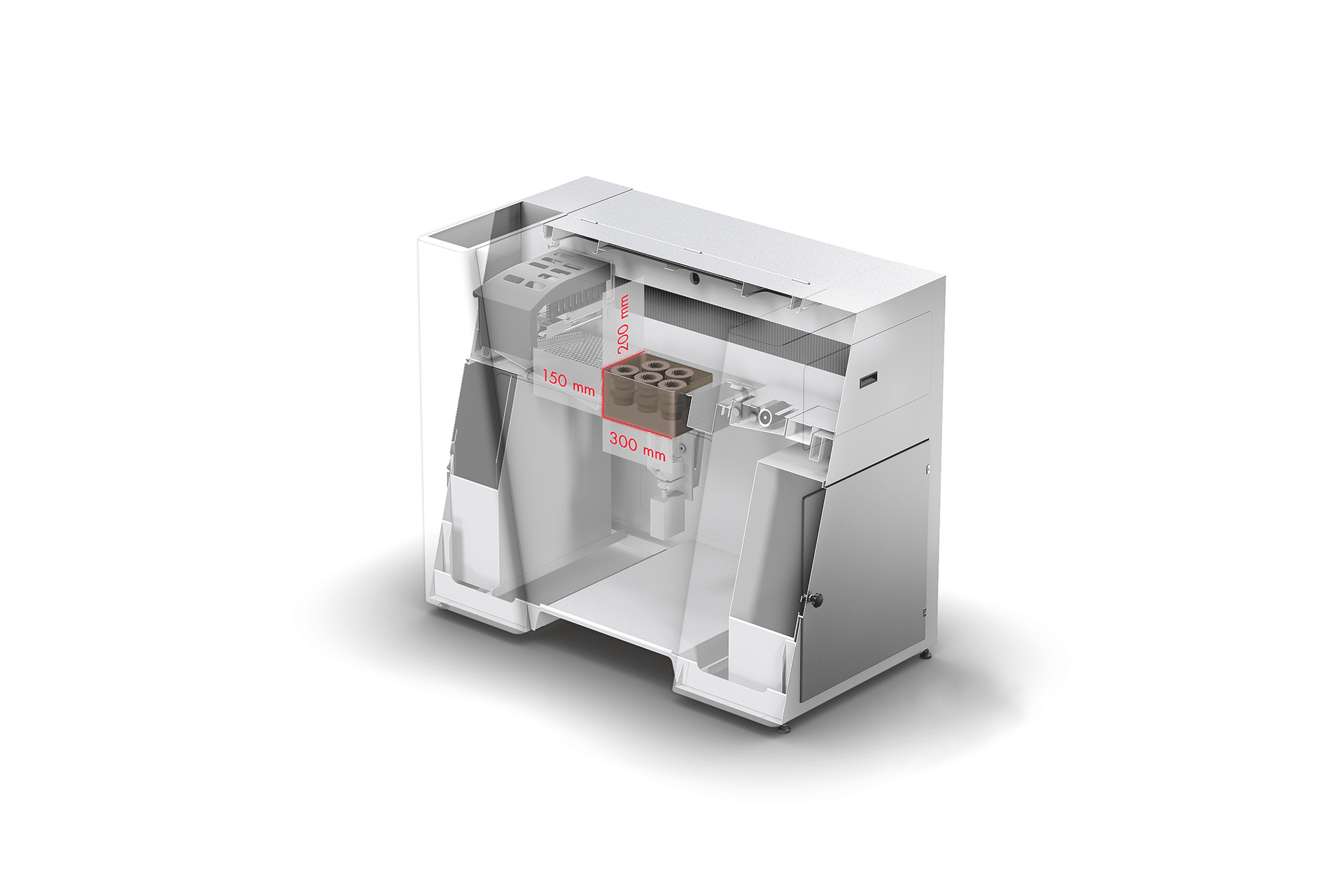

Mit einem Bauraum von 300 x 200 x 150 mm und Open-Source-Software ist die VX200 ideal für die Materialentwicklung und den 3D-Druck von kleinen, komplexen Bauteilen geeignet.

Die VX200 ist geeignet für:

99% Forschung und Entwicklung

20% Prototyping

10% Kleinserien

Flexibel in der Produktion

Schneller, variantenreicher – ohne hohe Vorlaufkosten. Binder-Jetting-3D-Druck bietet der Industrie in allen Bereichen, in denen Geschwindigkeit und Flexibilität gefordert sind, entscheidende Wettbewerbsvorteile. Und darüber hinaus eröffnet die additive Fertigung der Entwicklung in Design und Funktion völlig neue Möglichkeiten in der Konstruktion.

Time to market – Durch verkürzte Entwicklungs- und Produktionszeiten in Design und Funktion führen Sie Ihre Produkte deutlich schneller zur Marktreife.

Geometrische Freiheit – Die additive Produktion hebt die fertigungstechnischen Limitierungen konventioneller Verfahren auf. Druckbar ist, was konstruktiv denkbar ist. Für Produkte, die leichter und effizienter sind oder schlicht die Grenzen des bisher Machbaren sprengen.

Skalierung – Sind größere Bauteile oder höhere Stückzahlen gefragt, können Sie die Produktion innerhalb der voxeljet VX-Serie ganz einfach auf andere, größere Systeme derselben Serie verlagern.

Der Druckprozess Binder Jetting

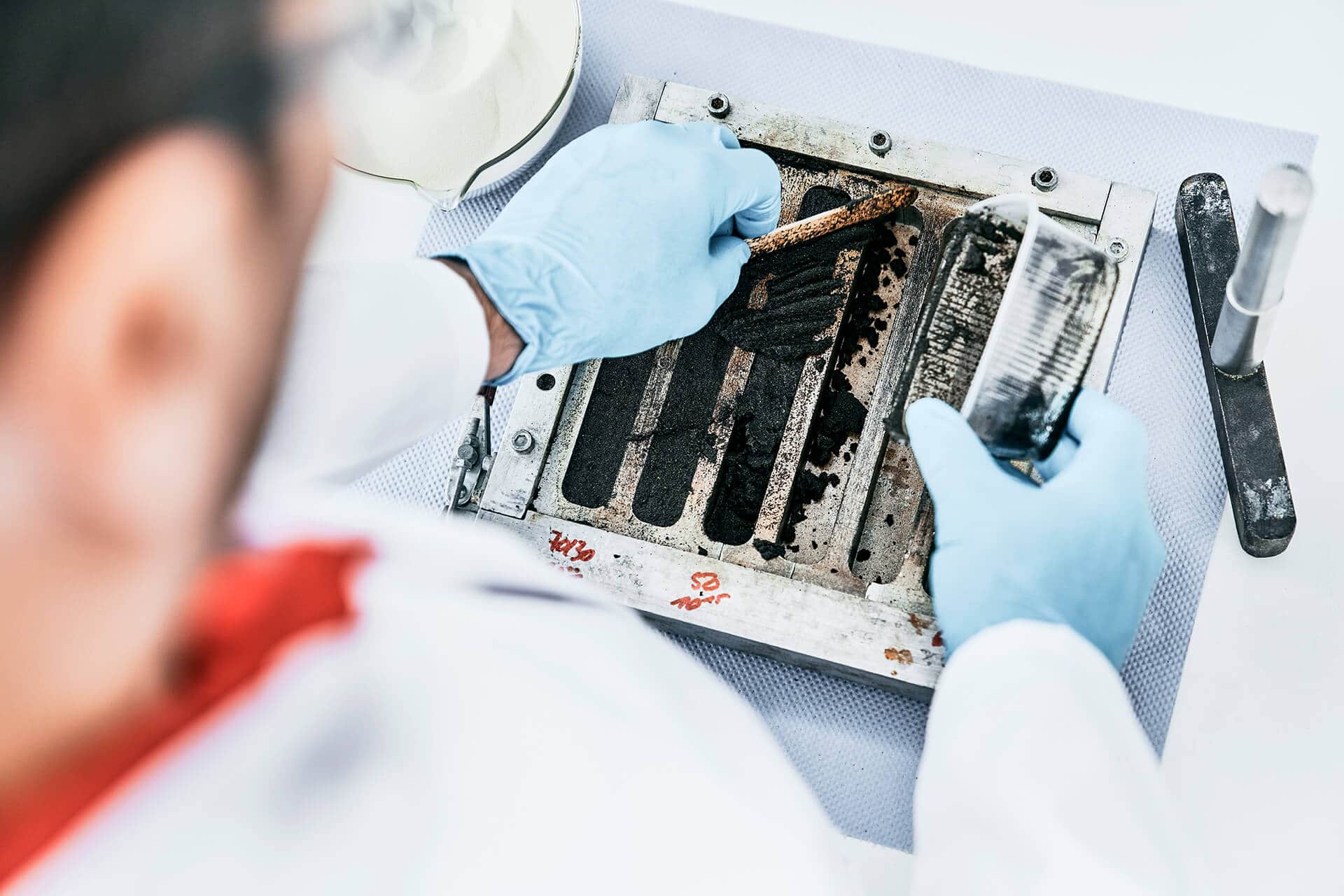

Das Binder-Jetting-Verfahren ist ein 3D-Druckverfahren, bei dem in dünnen Schichten aufgetragenes Pulvermaterial selektiv mit einem Binder verklebt wird.

Aufgrund steigender Nachfrage an hochwertigen Quarzsanden im Bereich 3D-Sandguss, wird das Drucksystem VX200 in unserem Unternehmen zur Qualitätssicherung und Produktentwicklung eingesetzt. Die benutzerfreundliche Oberfläche macht eine flexible und leichte Anpassung der Prozessparameter auf unterschiedliche Gießereisande möglich. Somit erlaubt es die schnelle Umsetzung kurzfristig geplanter Versuchsreihen mit zeitnaher Ergebnisbetrachtung.

Firma Strobel Quarzsand GmbH

Technische Daten

Die hochauflösenden, piezoelektrischen Druckkopfmodule bieten höchste Leistungsstabilität und ermöglichen – je nach Material – eine Auflösung von bis zu 254 dpi. So ist die VX200 in der Lage, selbst komplexeste Bauteilgeometrien mit beeindruckender Präzision zu realisieren.

Verfahren:

voxeljet Binder Jetting Verfahren

Auflösung:

Bis zu 254 dpi

Bauvolumen:

9 Liter pro Job

Jobboxmaße:

Höhe 150 mm, Länge 300 mm, Breite 200 mm

Prozess

Unser Prozess ist furanharzbasiert (ODB) und ist ideal, für die hohen Qualitätsforderungen diverser Industrien.

Sandsorten

Wir bieten klassischen Quarzsand mit unterschiedlichen Korngrößen an.

Nachbearbeitung

Die Nachbearbeitung erfolgt durch Epoxidharz Infiltration oder Versiegelung. Sofern die Teile nicht für den Gussprozess verwendet werden.

Prozess

Unser Keramikprozess ist Wasser basiert (CDB) und eignet sich optimal, für die Herstellung von komplexen und filigranen Kernen oder Formen.

Materialien

Mit unseren Keramikprozessen lass sich Slikat (SiC) und Oxid (AIO2, TiO2, ZrO2) basierte Keramiken verdrucken.

Support &Services

Sie haben konkrete Fragen zu den innovativen Einsatzmöglichkeiten von 3D-Druck in Ihrer Produktion. Sie möchten Maschinen autonom warten oder neue Materialien qualifizieren. Ihre Fragen zur Optimierung der Produktion mit additiven Fertigungstechnologien stehen bei voxeljet an erster Stelle.

voxeljet Academy

Lernen Sie alles über die Möglichkeiten, wie additive Fertigung Ihre Produktion noch effizienter macht. Oder erfahren Sie von 3D-Druck-Experten aus erster Hand, wie digital getriebene Produktion Ihre Branche verändern wird.

Material Certification Lab

Das Zusammenspiel zwischen Material und Maschine ist unsere Leidenschaft. Wir sind bereit mit Ihnen innovative neue Wege zu gehen und helfen neue, oder spezifische Materialien auf 3D-Druckern zu testen und für die additive Fertigung zu qualifizieren.

Intelligente Finanzierung

Die smarte Finanzierung von neuen Prozessen und Produktionsverfahren setzt beim Finanzierungspartner tiefe Branchen- und Marktkenntnis voraus.

Kontakt

Sie interessieren sich für unser industrielles 3D-Drucksystem VX200 oder für die 3D-Druckdienstleistung

3D-Drucklösungen

Sie möchten mehr über uns und den 3D-Druck erfahren? Hier geht’s zum gesamten Lösungsportfolio von voxeljet.