Support & Services

Materialzertifikation Lab

Gemeinsam mit voxeljet Experten die Zukunft formen

- Home

- Support und Services

- Material Zertifikation Lab

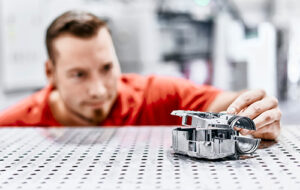

3D Material Zertifikation

mit höchster Expertise

Das perfekte Material für Ihre 3D-Anwendung definieren. In der Verarbeitung optimal abgestimmt auf performante und nachhaltig verfügbare Prozesse im industriellen Produktionsalltag. Das ist seit über 20 Jahren eine der Kernkompetenzen von voxeljet und eines der Geheimnisse hinter der Leistungsfähigkeit und Produktivität unserer 3D-Systeme. Aber das voxeljet Xperience Lab kann noch viel mehr. Es ist auch ein Think-Tank, in dem permanent daran gearbeitet wird, die Möglichkeiten der additiven Fertigung zu erweitern. So werden hier beispielsweise neue Material Binder Kombinationen getestet, um noch feinere Strukturen und Oberflächen in Bereichen von 100 μm herzustellen. Nicht ohne Grund hat voxeljet mit der VX200 ein frei parametrisierbares 3D Drucksystem geschaffen, um das Zusammenspiel von Material und Maschine weiter zu perfektionieren. Um die Zukunft der Produktion aktiv mitzuformen.

Sicher produzieren

Im voxeljet Xperience Lab werden alle Materialien optimal auf Ihre Prozesse und Produkte abgestimmt und zertifiziert. Für maximale Effizienz in der Produktion.

Expertise für Innovation

Erforschen Sie gemeinsam mit den Experten im Xperience Lab neue Materialien und Möglichkeiten für die Herstellung innovativer Produkte.

Teste die Möglichkeiten

voxeljet zählt zu den Pionieren und Innovationstreibern der additiven Fertigung. Was immer sie in 3D herstellen möchten: Wir sind gerne an Ihrer Seite.

Das Xperience Lab und seine Leistungen

Im voxeljet Material Xperience Lab ermöglichen wir unseren Kunden, spezifisches Material auf voxeljet 3D-Drucksystemen zu testen. Und für den nachhaltigen Einsatz in der Produktion zu zertifizieren. Der Umfang der Klassifizierungsstufen bezieht sich auf das jeweilige Herstellungsverfahren und kann im Bedarfsfall an Ihre individuellen Anforderungen angepasst werden. Das Angebot umfasst folgende Leistungen:

- Optimierung von Material Binder Kombination für spezifische Produktionsprozesse oder Produkte

- Optimierung der Prozessparameter in den 3D-Drucksystemen für perfekte Ergebnisse in der Produktion

- Zertifizierung von spezifischen Materialien, wie Sanden, Polymeren, Keramikpulver und Binder zur Verwendung auf voxeljet 3D-Drucksystemen

- Prüfen der Produktionssicherheit von neuen Produkten auf voxeljet 3D-Drucksystemen im Vorfeld – auch in Testserien

Die Expertise

unserer Experten

Die voxeljet 3D Experten im Xperience Lab verfügen über einen langjährigen, reichen Erfahrungsschatz über die additive Fertigung im industriellen Umfeld. Über die Anforderungen der unterschiedlichen Branchen und Herstellungsverfahren. Sie wissen damit genau, welche Kriterien bei Produkten aus der additiven Fertigung entscheidend sind. Und damit auch welche Normen Materialien erfüllen müssen, um perfekte Bauteile oder Produkte in 3D herzustellen. Um sie im Einzelfall sofort zu verwenden, oder nahtlos in die weiteren Produktionsprozesse einzuschleusen.

Customer Story: Frauenhofer IPA

In diesem Webinar werden wir gemeinsam mit dem Fraunhofer IPA durch das HSS-Materialnetzwerk und seine Expertise bei der Entwicklung neuer Materialien für HSS führen.

Das voxeljet High Speed Sintering wird durch exzellente Material-Kombinationen renommierter Partner aus der Chemischen Industrie supportet.

Das Zusammenspiel aus hoch-performanten Material und der Flexibilität des voxeljet 3D Polymer High Speed Sintering (HSS) Verfahrens ist der entscheidende Faktor für optimale physische Bauteileigenschaften, höchste Präzision und ausgezeichnete Qualität der Oberflächen. Mit unseren Partnern aus der chemischen Industrie arbeiten wir kontinuierlich daran, das Spektrum der verfügbaren Materialien, um neue Polymerwerkstoffe zu erweitern.

Aktuell wird das voxeljet High Speed Sintering Verfahren von folgenden Herstellern aktiv unterstützt:

3D HSS Polymer Sintering

voxeljet Polymer High Speed Sintering für voll funktionale 3D Kunststoffbauteile

3D Polymerdruck – State of the Art. voxeljet High Speed Sintering (HSS) ist eine extrem leistungsstarke von voxeljet entwickelte 3D-Drucktechnologie, für die hochperformante Herstellung von präzisesten Polymerteilen. Und das in Kunststoffspritzguss vergleichbarer Qualität und Haltbarkeit. Im Gegensatz zu herkömmlichen Verfahren erfolgt das Sintering nicht über komplexe Lasertechnologie, sondern pixelgenau über wärmereaktive Binder. High Speed Sintering ist damit in der Anwendung äußerst zuverlässig und robust, extrem schnell und sorgt für hohen Output auch bei großvolumigen Objekten. Das Verfahren ermöglicht den Einsatz einer großen Bandbreite an Polymeren, wie zum Beispiel PA12, PP, TPU, PEBA und auch EVA.

3D Universal Binder Jetting

voxeljet Universal Jetting für 3D Sand-, Kunststoff- und Keramikdruck

Performanter 3D-Druck mit überragender Materialfreiheit. voxeljet Universal Binder Jetting (UBJ) ist eine extrem leistungsstarke von voxeljet entwickelte 3D-Drucktechnologie für die Herstellung von hochpräzisen Sand-, PMMA- und Keramikdrucken. Zum Beispiel für die industrielle Produktion von Sandkernen für den Metallguss. Im Gegensatz zu herkömmlichen Verfahren wird der Binder punktgenau kontrollierbar inline in der Maschine verarbeitet. Für optimal gesteuerte Ergebnisse mit dynamischer Inline Inkjet-Technologie. Technik die agil auf die speziellen physikalischen Anforderungen an Ihre Bauteile reagieren kann. Alle 3D Drucksysteme setzen auf hochwertige, eigens entwickelte Druckköpfe, die für den 24/7 Betrieb ausgelegt wurden.

VX200: Der flexible Einstieg in den multimaterialien industriellen 3D-Druck

Freie Parameter und eine einfache Bedienung: Die VX200 bietet das höchste Maß an Flexibilität in puncto Materialentwicklung in der voxeljet System-Serie. Ob neue Binder- und Pulverkombinationen oder die schnelle Produktion von Bauteilen zur Eigenschaftsüberprüfung. Mit der voxeljet Open-Source Software können Prozessparamter auf individuelle 3D-Druck Materialien abgestimmt werden.

Kontakt

Industrielle 3D-Drucksysteme

Unser Portfolio an industriellen 3D-Druckern reicht vom kompakten System für die Forschung bis zur additiven Serienfertigung.