- Home

- Case Studies

- Luft- und Raumfahrt

voxeljetCase StudiesLuft- und Raumfahrt

Wie neue additive 3D-Fertigungsverfahren den Flugzeugbau von morgen voranbringen. Die Flugzeuge der Zukunft werden immer leichter. Gleichzeitig rücken Produktionseffizienz und Fertigungsgeschwindigkeit zunehmend in den Fokus der Flugzeugbauer und ihrer Zulieferer. Ein Schlüssel hierzu ist die das voxeljet Binder Jetting Verfahren. Ohne Einschränkungen bei Individualisierung, Leichtbau und anspruchsvollen oder komplexen Geometrien. Und nicht zu vergessen mit einem großen Potenzial zur Kostenoptimierung im Herstellungsprozess. Die positive Folge: ein geringerer Treibstoffverbrauch und CO2-Ausstoß.

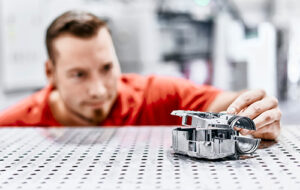

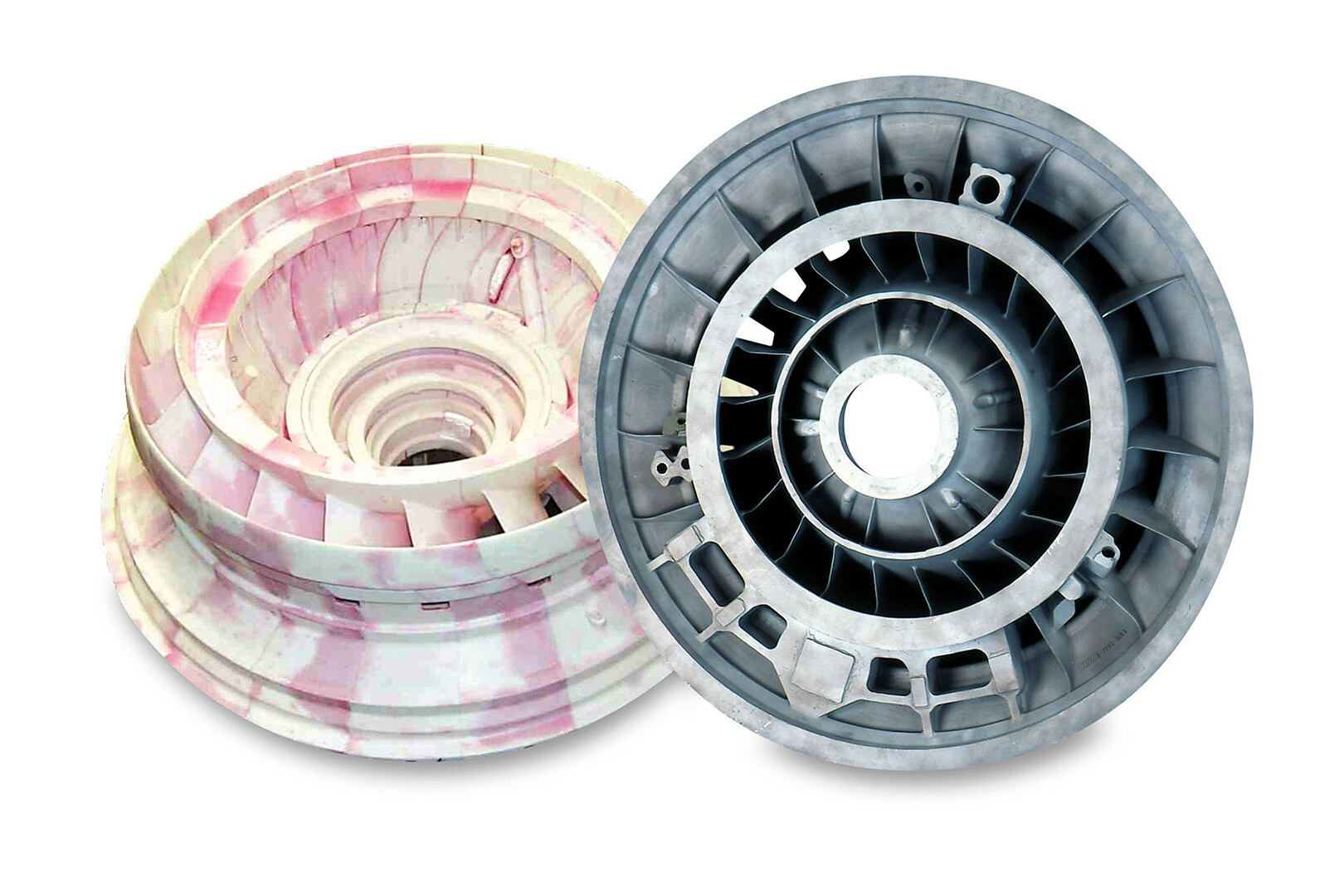

3D-Druckmodelle für Aluminium- und Titan-Feingussspezialist TITAL

Der Luft- und Raumfahrtexperte TITAL setzt bei der Herstellung von Gussmodellen für Titan und Aluminium auf den 3D-Druck von PMMA

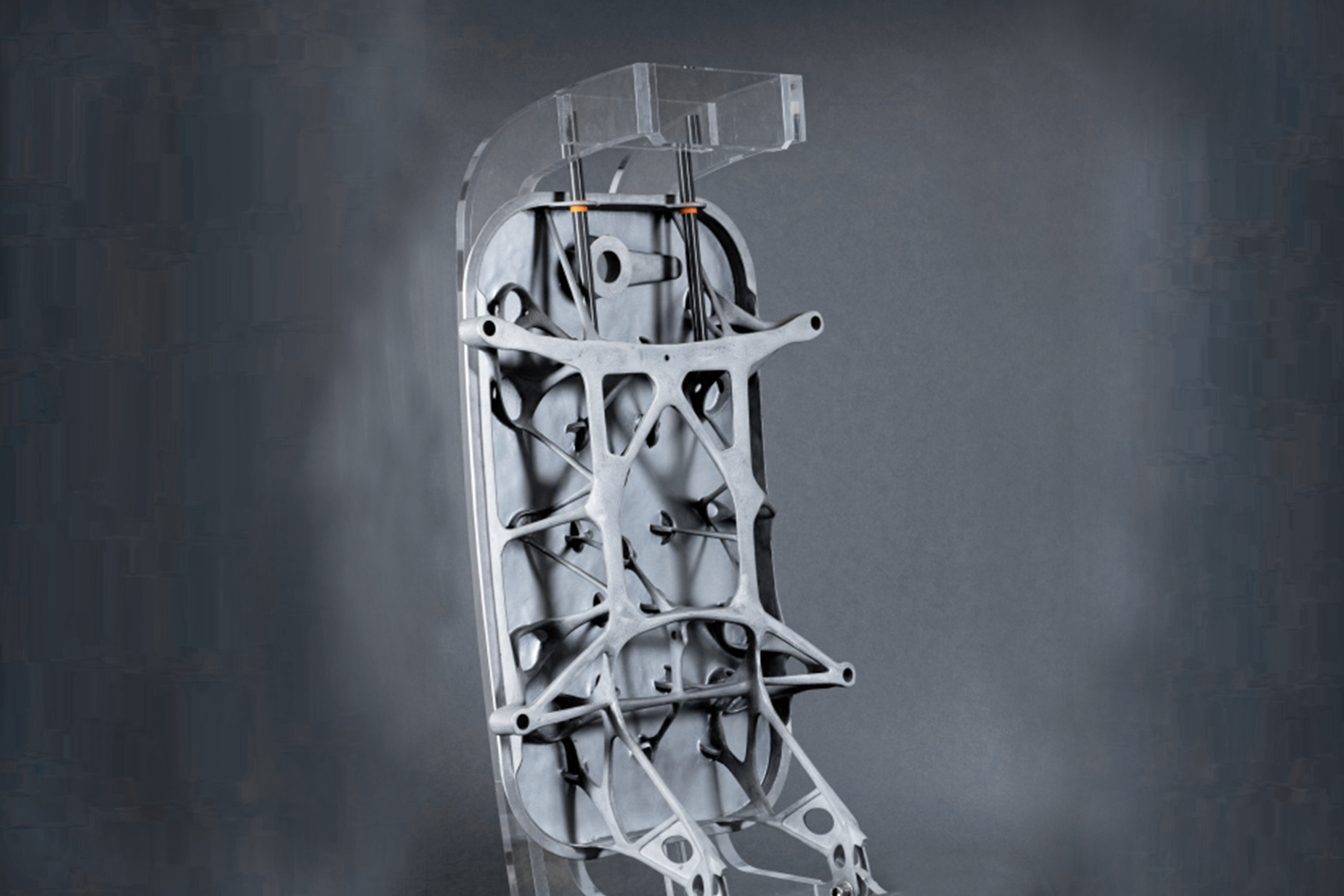

Topologieoptimierung in der Luftfahrt

voxeljet ermöglicht schnellen, kostengünstigen und flexiblen Feinguss bei französischen Luftfahrtzulieferer Sogeclair.

Leistungsfähigkeit von Bauteilen effizient steigern

Wie kann die Leistungsfähigkeit von Bauteilen bei gleichem Gewicht um ein vielfaches gesteigert werden?

Hyperloop-Konzept delft

Für das Hyperloop Projekt in den USA hat voxeljet die TU Delft mit komplexen, additiv gefertigten Kunststoff-Modellen für den Feinguss unterstützt.

Kontakt

Möchten Sie mehr erfahren? Dann fragen Sie uns. Wir helfen Ihnen gerne weiter.

Industrielle 3D-Drucksysteme

Unser Portfolio an industriellen 3D-Druckern reicht vom kompakten System für die Forschung bis zur additiven Serienfertigung.