3D-Drucklösungen

3D-Druck im Sandguss.

Agiler handeln. Kosten senken.

- Home

- 3D-Drucklösungen

- Casting Sandguss

Die beste Verbindung aus zwei Welten: Additive Hybrid Manufacturing für den Guss

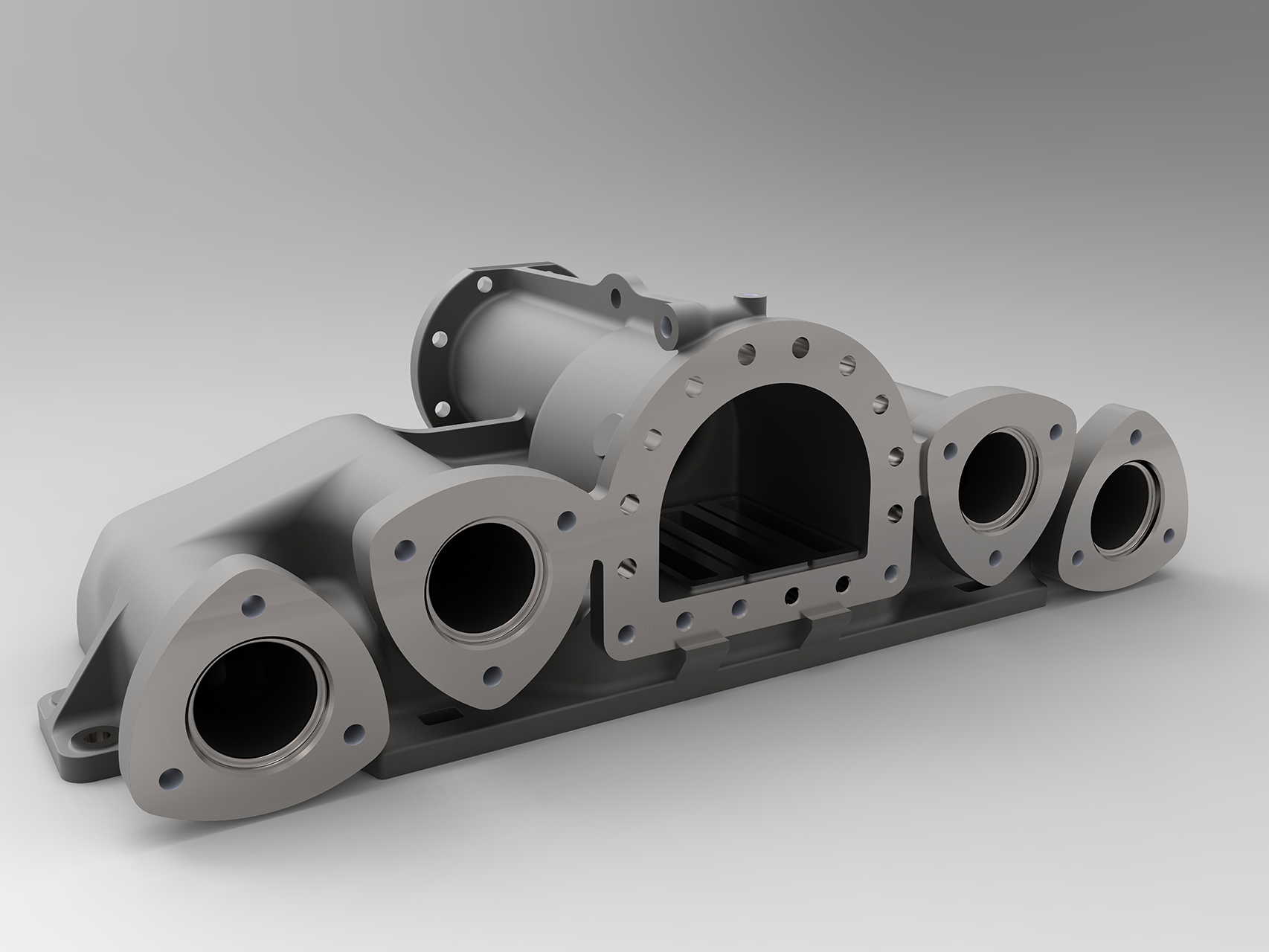

Die Gussindustrie befindet sich im Umbruch. Die Fähigkeit, immer komplexere Formen, volatile Stückzahlen und kurze Lieferzeiten realisieren zu können, werden zunehmend wichtigere Erfolgsfaktoren im Wettbewerb. voxeljet setzt auf die intelligente Fusion klassischer Gießereitechnologien mit flexiblen additiven Produktionsverfahren. Zur nachhaltigen Optimierung und Effizienzsteigerung über die gesamte Wertschöpfungskette der Fertigung hinweg.

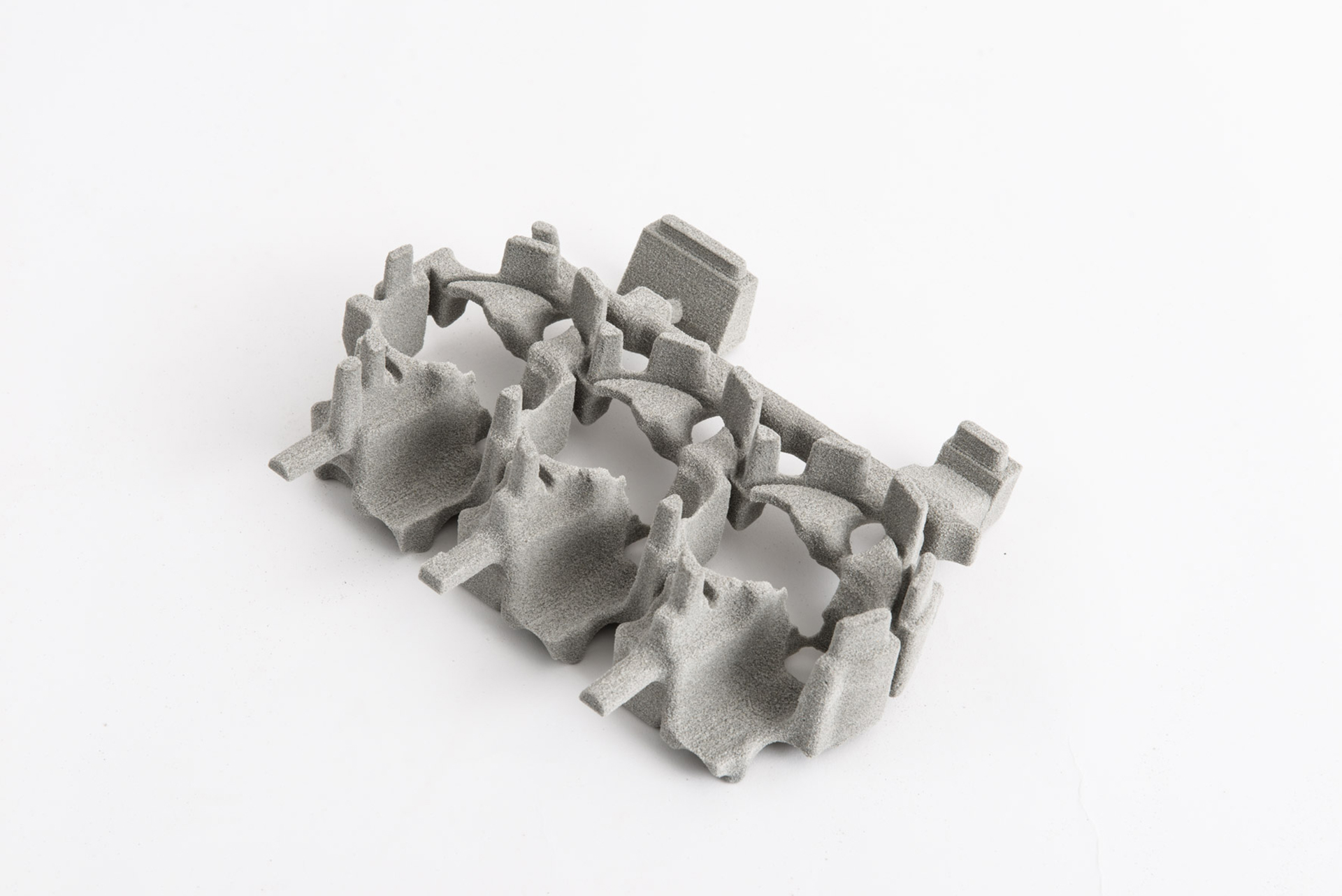

Vom Prototyping und der Ersatzteilproduktion bis hin zur agilen industriellen Serienfertigung. Mit der Universal Binder Jetting 3D-Drucktechnologie und der werkzeuglosen Herstellung von 3D-Sandformen und -kernen für klassische Metallgussverfahren eröffnen wir der Gießereiindustrie neue Horizonte. Ohne Einschränkungen bei Individualisierung, Leichtbau und anspruchsvollen oder komplexen Geometrien. Und nicht zu vergessen: mit einem großen Potenzial für die Kostenoptimierung im Herstellungsprozess.

Das Hybrid Manufacturing-Verfahren sichert der Gießereiindustrie Wettbewerbsvorteile – in jedem Format, technisch und wirtschaftlich

Kosten optimieren

Komplexe Geometrien und immer variantenreichere und kleinere Losgrößen. Wo immer konventionelle Verfahren durch kostenintensiven Formenbau oder Umrüstzeiten an ihre wirtschaftlichen Grenzen stoßen, bieten 3D-Produktionsverfahren essenzielle wirtschaftliche Vorteile. Komplett digital und werkzeuglos produziert, verlieren Hinterschneidungen oder Entformungsschrägen in der Kalkulation ihre Bedeutung und können kostenoptimiert produziert werden.

In jedem Maßstab produzieren

voxeljet verfügt weltweit über die größten und leistungsfähigsten 3D-Drucksysteme für große Bauteile oder große Auflagen kleiner Bauteile. Wir heben damit bestehende Grenzen herkömmlicher 3D-Drucksysteme und -verfahren auf. Der Einsatz gießereiüblicher Materialien wie Sand und komplementärer Binder gewährleistet dabei durch die nahtlose Integration in die klassischen Produktionsverfahren optimale Gussergebnisse.

Time to Market beschleunigen

Durch den Wegfall des Werkzeug- bzw. Formenbaus verkürzen additive Produktionsverfahren die Herstellungszeiten von Bauteilen um bis zu 75 %. Das 3D-Druckverfahren ermöglicht die Fertigung in einem einzigen, kompakten Produktionsschritt. Sandformen und -kerne lassen sich in nur wenigen Stunden herstellen. Das bedeutet eine Zeiteinsparung von mehreren Wochen.

Durch den Einsatz der Binder Jetting Technologie von voxeljet können wir die Lieferzeit von Formen und Kernen für unsere Kunden deutlich verkürzen. Darüber hinaus erzielen wir neue Bestmarken in Bezug auf Größe und Gewicht der Teile, die wir vergießen.

Oliver JohnsonGeschäftsführerTEI

TEI, USA setzt aufvoxeljet Hybrid Manufacturing

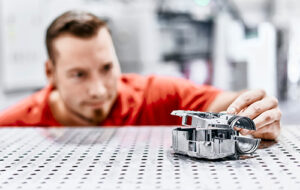

Die voxeljet 3D-Druck-Experten für Sandgussformen und -gusskerne sind an Ihrer Seite

Von der Beratung und Planung Ihrer hybriden Produktionsprozesse bis hin zur Auswahl der perfekten Sand/Binder-Kombination für Ihre Bauteile und Verfahren.

Unsere additiven Systeme für Sandgussformen und -kerne

voxeljet unterstützt Sie – vom schnellen Prototypenbau über effiziente Maschinen und mittelgroße Serienaufträge bis hin zu den weltweit größten und leistungsfähigsten 3D-Drucksystemen für die additive Massenfertigung, ob große Bauteile oder große Auflagen kleiner Bauteile. Mit einer Vielzahl möglicher Sand/Binder-Kombinationen und der Möglichkeit, zwischen der Fertigung auf Basis von Furan- oder Phenolharzen oder anorganischen Bindern frei zu wählen. Sie können Formen und Kerne auch durch eines unserer weltweiten 3D-Dienstleistungszentren beziehen, um Prozesse ohne eigenes Investment in Hardware auf Herz und Nieren zu testen sowie Produkte zu optimieren oder deren Entwicklung zu beschleunigen.

VX1000

Die VX1000 ist der Alleskönner für die 3D-Produktion. Mit ihrem Bauvolumen von 1000 x 600 x 500 mm kann sie Kunststoffe, Sande und Keramik verarbeiten. Von mittelgroßen Formen und Kernen für den Metallsandguss über Feingussmodelle bis hin zu keramischen Bauteilen.

VX1300 X

Die VX1300 X ist der Wegbereiter für die additive Massenfertigung im industriellen Maßstab. Bereit für die Integration in IoT-Produktionsumgebungen und perfekt auf die automatisierte Nachbearbeitung abgestimmt, definiert sie die Optimierungsoptionen in der Wertschöpfungskette neu.

VX2000

Die VX2000 ist ein extrem leistungsstarkes, robustes 3D-Drucksystem für industrielle Anwendungen. Mit einer Jobbox von 2.000 Litern zählt sie zu den weltweit produktivsten 3D-Drucksystemen. Kompatibel mit vielen Sanden und allen Furan- und Phenolharz-Bindern von voxeljet.

VX4000

Die VX4000 ist mit einem zusammenhängenden Bauraum von 4 x 2 x 1 Meter das weltgrößte 3D-Drucksystem für Sandformen. Mit seinem patentierten Schichtbauverfahren gewährleistet das System konstante Bauzeiten und beeindruckende Präzision und Bauteilqualität in nahezu jedem Format.

3D-Sandguss.Material.Werkstoffe.

voxeljet zählt zu den Pionieren der ersten Stunde, wenn es um die Etablierung von 3D-Produktionsverfahren im professionellen oder industriellen Umfeld geht. voxeljet 3D-Drucksysteme sind ausgestattet mit modernster Technik für den 24/7-Betrieb. Unsere speziell für den Industrieeinsatz entwickelten Universal Binder Jetting Maschinen zählen zu den besten, die der Markt weltweit zu bieten hat. Besonders, wenn es auf Volumen, Effizienz und Geschwindigkeit in der Fertigung ankommt. Hier eine Auswahl an bereits ab Werk zertifizierten Werkstoffen für die additive Fertigung für den Sandguss.

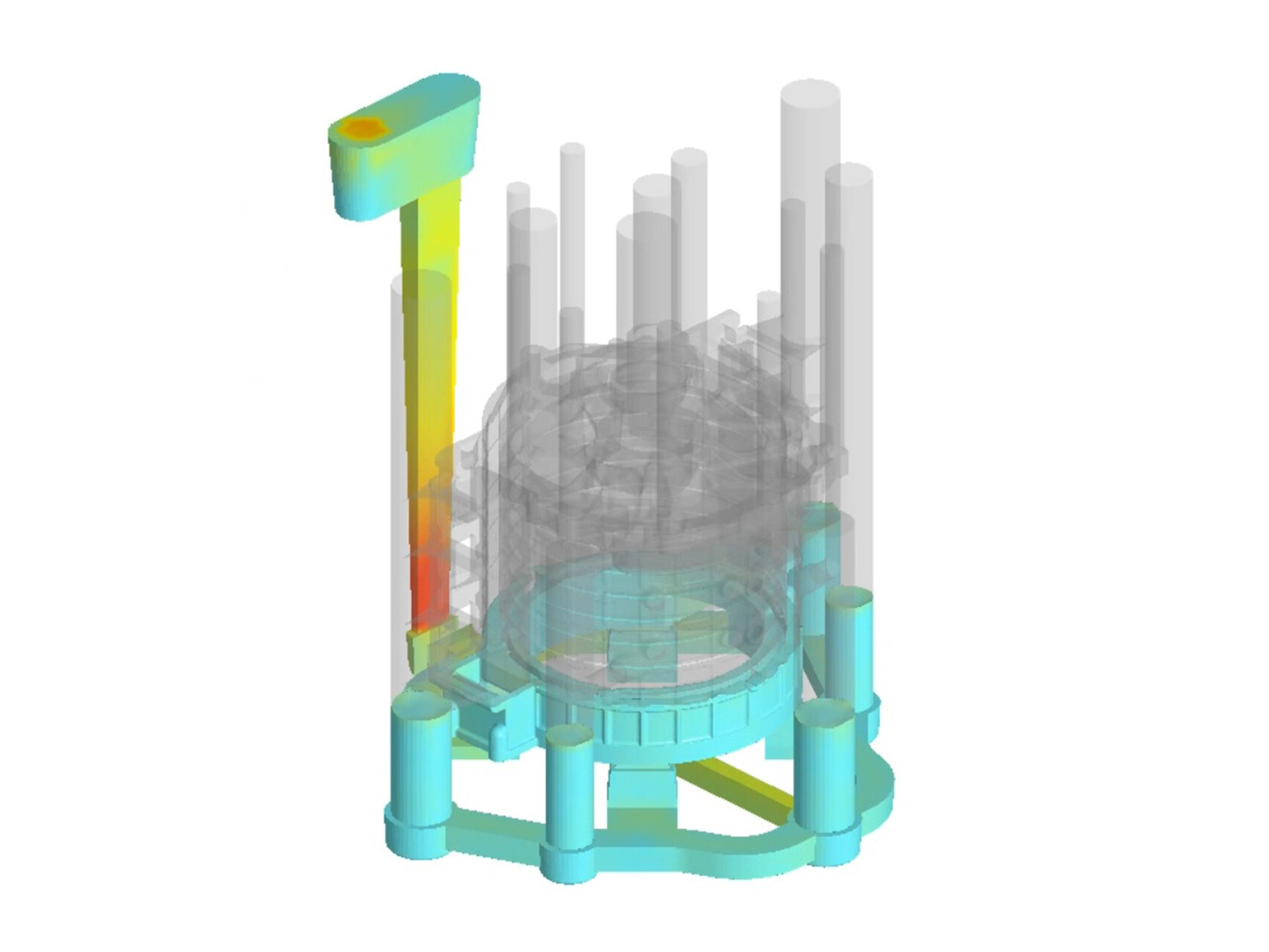

Prozesse

Unsere Prozesse sind furanharzbasiert, phenolharzbasiert oder wasserglasbasiert und ideal für die hohen Qualitätsforderungen der Gießereiindustrie.

Sandsorten

Wir bieten neben klassischem Quarzsand mit unterschiedlichen Korngrößen auch Cerabeads und Chromerz an.

Nachbearbeitung

Die Nachbearbeitung erfolgt durch Epoxidharz-Infiltration oder -Versiegelung. Sofern die Teile nicht für den Gussprozess verwendet werden.

Legierungen

Mit maximalem metallurgischem und gießtechnischem Know-how. In eingespielten Prozessen verwirklicht voxeljet mit erfahrenen Netzwerk-Partnern aus der Gießereibranche Projekte schnell, wirtschaftlich und nach deutschen Qualitätsstandards. In Aluminium, Magnesium, Stahl, Eisen, Titan und Bronze.

Workshop: Sand 3D-Druck

In diesem Webinar werden wir einen tiefen Einblick in unsere 3D-Drucklösungen für den Metallguss geben.

Die voxeljet 3D-Systeme verändern die Parameter im Formenbau nachhaltig – technisch und wirtschaftlich. Durch den Wegfall von teurem Formenbau und die problemlose Realisierung von Hinterschnitten, komplexen Geometrien oder dünnwandigen Strukturen. Mit Freiheitsgraden, die weit über die Möglichkeiten des konventionellen Formenbaus hinausreichen und sich dennoch ganz einfach in bestehende Produktionslandschaften integrieren lassen.

voxeljet Highlights aus der Casting-Industrie

3D-Druck und Schalungsbau in Perfektion. Für ein Museum im Schwarzwald setzt voxeljet neue Maßstäbe für die additive Fertigung in der Architektur.

Boro Foundry – Superheater Header

Aus der Kombination Sand-3D-Druck konnte die britische Gießerei Boro Foundry ein makelloses Ersatzteil für eine Dampflok herstellen.

Mit 3D-Druck zum Optimierten Elektromotor

Aiona Cast hat ein Patent angemeldet mit dem sich Elektromotoren deutlich optimieren lassen. Einen Prototyp fertigte das Unternehmen mit 3D-Druck an.

Die schnellste Gießerei Skandinaviens

Mit einer neuen VX2000, einem 3D-Sanddrucker für Metallguss stellt Hetitec fertige Gussteile in wenigen Tagen her.

Printed Casting Gehäuse für E-Motorrad

Durch den Einsatz innovativer Technologien wie dem 3D-Druck könnte der Prototyp schon bald in Serie gehen.

Printed Castings: 3D-Druck für den Leichtbau und die Elektromobilität

Vor der Serienreife zum perfekten Prototypen. Die britische Gießerei BCP setzt nicht nur bei Elektromotorgehäusen auf 3D gedruckte Formen und Kerne.

Printed Casting – 3D-Druck für Gießereien

Mittels Binder Jetting lassen sich Geschäftsmodelle für den Sand-Metallguss und Feinguss optimieren, besonders für die Produktion technischer Prototypen.

Support &Services

Sie haben konkrete Fragen zu den innovativen Einsatzmöglichkeiten von 3D-Druck in Ihrer Produktion? Sie möchten Maschinen autonom warten oder neue Materialien qualifizieren? Ihre Fragen zur Optimierung der Produktion mit additiven Fertigungstechnologien stehen bei voxeljet an erster Stelle.

Additive Production Backup

Als Security Pack für die reibungslose Produktion bietet voxeljet bei Inbetriebnahme, ungeplanten Stillstandzeiten und Lastspitzen unsere Produktionszentren als Backup-Kapazität zu speziellen Konditionen an.

Distribution weltweit

voxeljet ist mit Sales und Services weltweit an Ihrer Seite. Gemeinsam mit unseren Partnern sind wir in 26 Ländern in Amerika, Asien, Afrika, dem Mittleren Osten und Europa präsent. Darüber hinaus verfügen wir über Produktionszentren auf drei Kontinenten.

Guss Lohnfertigung 4.0

Komplette Gussteile in Aluminium, Eisen, Magnesium, Stahl, Titan und Bronze direkt aus dem CAD-Datensatz. Mit komplexen Hinterschneidungen, werkzeuglos im 3D-Druck realisiert. Schnell und wirtschaftlich verwirklicht nach den hohen deutschen Normen und Standards.

Kontakt

Möchten Sie mehr erfahren? Dann fragen Sie uns. Wir helfen Ihnen gerne weiter.

Industrielle 3D-Drucksysteme

Neben industriellen 3D-Druckern bieten wir auch die Teilelieferung auf Anfrage an. Erfahren Sie hier mehr darüber.