- Home

- Additive Fertigung

- Case Studies

voxeljetCase Studies

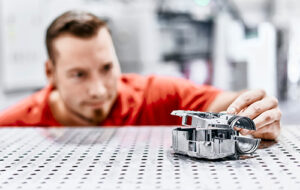

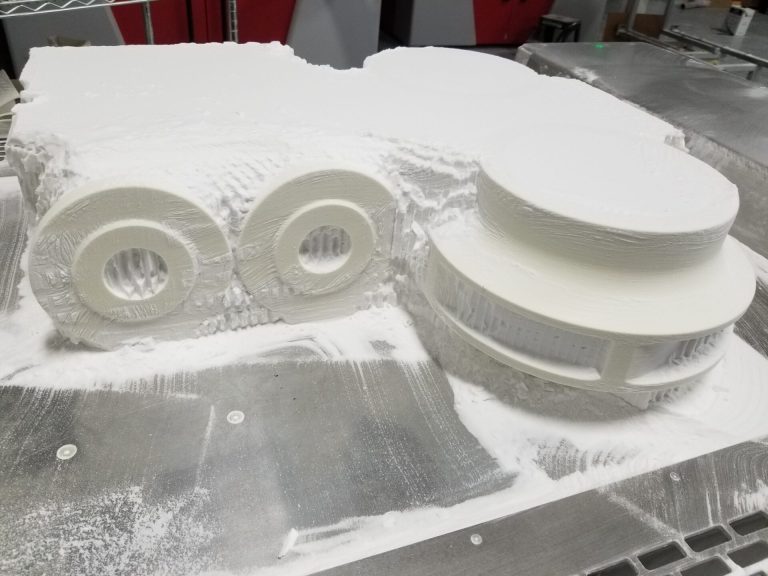

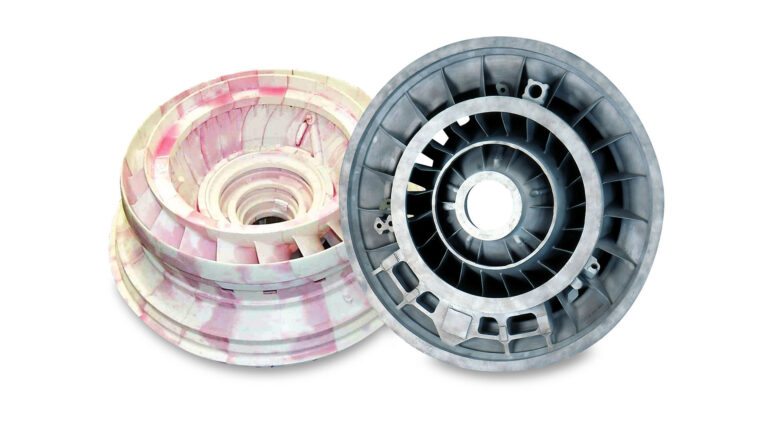

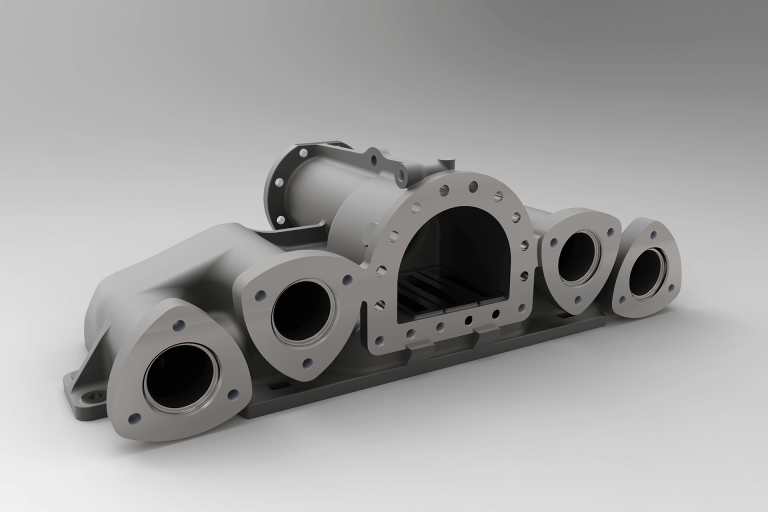

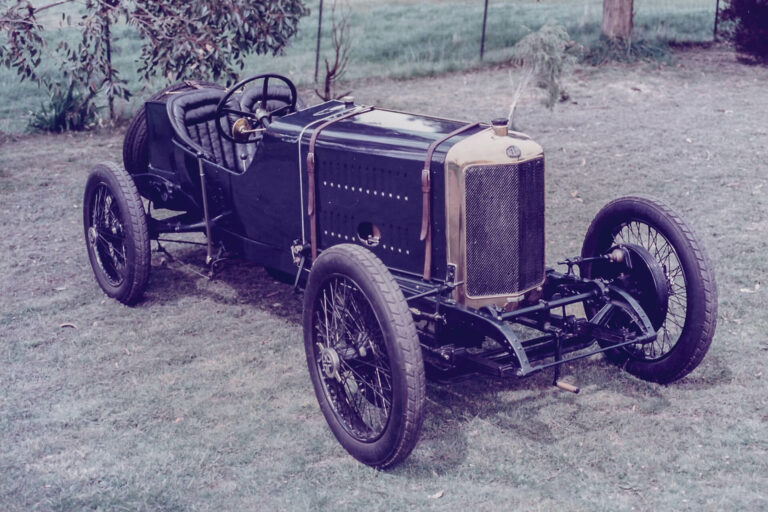

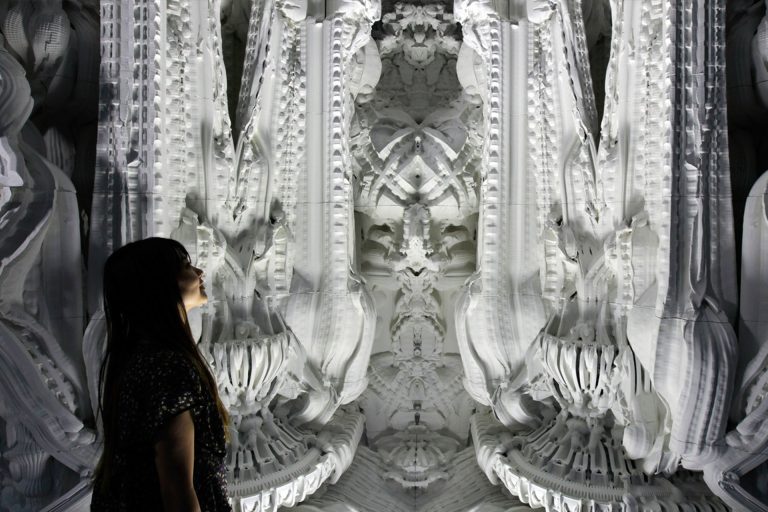

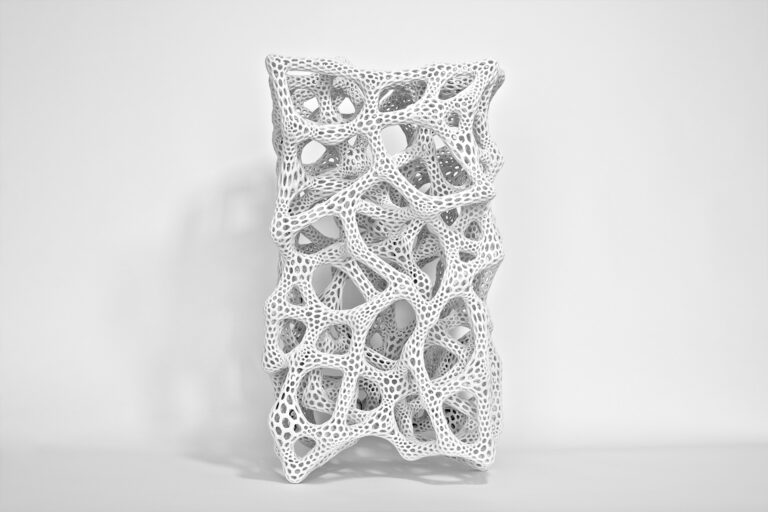

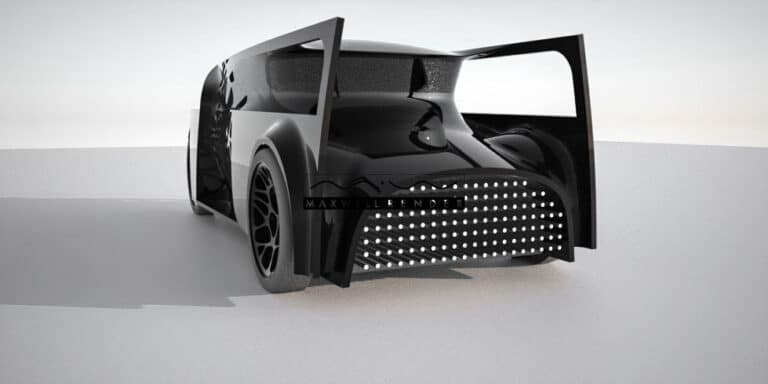

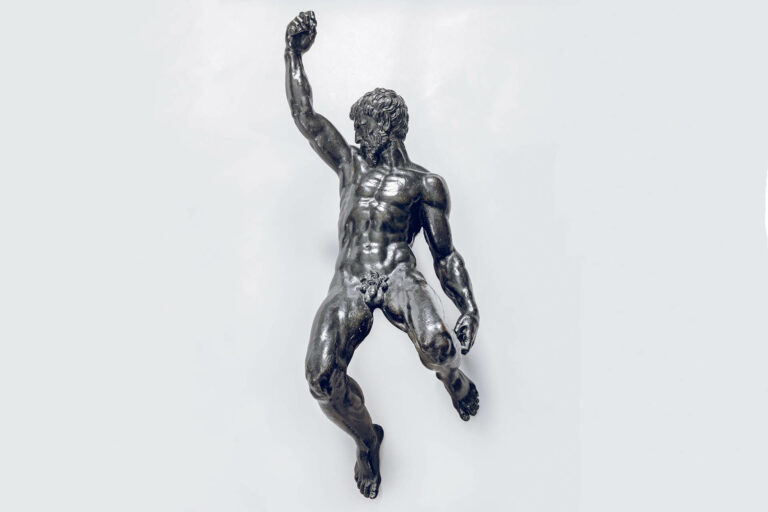

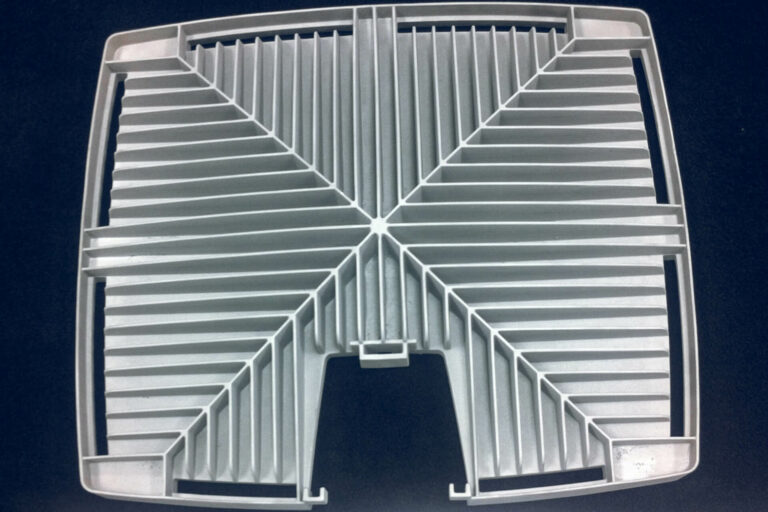

Ob in Design, Individualisierung, Leichtbau, Bionik oder bei iterativer Produktevolution. Additive Fertigung sprengt die Grenzen des bisher Machbaren. Wenn diese Möglichkeiten auf faszinierende neue Ideen stoßen, entstehen innovative Produkte, die das Potenzial haben unsere Welt zu verändern. Gemeinsam mit unseren Kunden sind wir bereit, dieses Neuland zu betreten. Um gemeinsam Zukunft zu gestalten. Lassen Sie sich von den Möglichkeiten inspirieren.

X Filter zurücksetzen

Auswahl lieferte kein Ergebnis

Kontakt

Möchten Sie mehr erfahren? Dann fragen Sie uns. Wir helfen Ihnen gerne weiter.

Industrielle 3D-Drucksysteme

Unser Portfolio an industriellen 3D-Druckern reicht vom kompakten System für die Forschung bis zur additiven Serienfertigung.

Scroll up